Together with our partners, we’re leading the charge to create a more sustainable future.

Let's ChatMade for Good

DATA CENTERS CASE STUDY

RESPONSIBLY MEETING CONSTRUCTION DEMAND TO SUPPORT AN INCREASINGLY DIGITAL WORLD

Led by the artificial intelligence boom and the demands of a digital-first economy, the number of new data centers being constructed is growing exponentially. It’s estimated that the data center construction market will see a CAGR between 7.5% and 8.1% between now and 2030*. Nucor, North America’s largest steel manufacturer and recycler, is positioned to help the industry build data centers more sustainably.

Domestic data center development is expected to grow to 31.9 million square feet in 2025. While critical to enabling a more connected future, data centers—ranging from smaller edge facilities to hyperscale data centers—are extremely steel intensive, and the steel with which these data centers will be built matters.

A MORE SUSTAINABLE SOURCE OF STEEL

Data center construction is both energy and material intensive. Nucor offers data center customers a more sustainable construction material option with low-embodied carbon circular steel products that can reduce a project’s total carbon footprint.

For over 50 years, Nucor has employed electric arc furnace (EAF) technology to produce steel. This recycling-based process uses scrap as its primary feedstock, along with other inputs, to create new high-quality, low-embodied carbon steel. As North America’s largest recycler, Nucor can transform reclaimed steel from things like decommissioned oil rigs, retired infrastructure, and end-of-life vehicles into new, advanced steel solutions for data centers—all with less than 1/3 of the carbon emissions compared to extractive, blast furnace steel making.

INDUSTRY-LEADING BREADTH OF DATA CENTER CONSTRUCTION PRODUCTS

Data center construction is comprised of two areas – the core and shell, and the white space. Core and shell refers to the structure of the building including structural steel, insulated metal panels for the roof and walls and rebar for the foundation. The white space of a data center refers to the interior part of the building that supports the IT equipment such as cabinets, racks, cages and steel structures for cooling and airflow containment.

As North America’s largest steel manufacturer, Nucor’s diversified breadth of steel products and capabilities offer reliable, domestic access to the majority of the steel material needed for data center construction.

YOUR PARTNER FOR SUSTAINABLE DATA CENTER CONSTRUCTION

- 300+ North American facilities offer a robust, reliable domestic supply chain.

- From the white space to the shell and everything in between, Nucor can supply a wide array of sustainable steel products for any data center.

- Nucor’s data center construction experts offer product and design solutions.

We are proud to be a partner for the leaders in the data center space, working from the project outset to ensure this critical infrastructure connecting our society is built with the most sustainable materials possible.

General Manager, Fabricated Products

Nucor collaborates with our data center partners to establish fully circular steel supply chains to build faster and more sustainably. Nucor also offers end-of-life recycling services for old data center racks and cabinets that need replacing, creating a closed loop cycle that is infinitely repeatable.

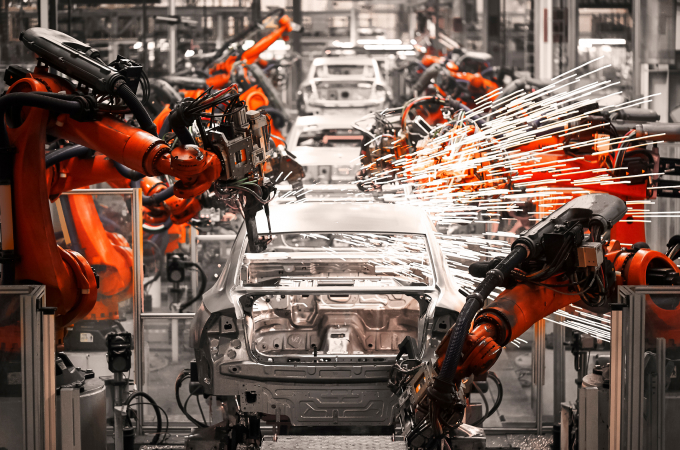

Nucor will continue to partner with customers across the data center space and other major industries, from automotive to tech and advanced manufacturing, sharing our learnings and jointly pursuing new ways to build sustainable supply chains and create a circular global manufacturing economy for the future of all.