Green Steel: Defining and Understanding Sustainable Steel

How can we impact the future of sustainable steelmaking? Let’s start by clearly defining common terms in the market to better understand sustainability within the steel industry.

Defining Green Steel: Low-Embodied Carbon Steel

Steel is an essential material for the global construction, manufacturing and automotive industries, and it currently accounts for 7-9% of global greenhouse gas (GHG) emissions. Because of this, the steel industry is working to decarbonize through a variety of methods and technologies, and many steel producers have set ambitious carbon reduction targets for the coming decades.

This increased focus on decarbonization in the steel industry has coincided with a growing interest among steel purchasers for “green steel” – a term that broadly refers to steel that is made in a more sustainable way and with fewer resulting emissions. However, there is no universal definition within the industry for what green steel is. As a result, the term “green steel” is used to represent a wide range of steel products and steelmaking processes that can vary significantly in their carbon intensities. This gap is widened by inconsistencies across the industry with regard to carbon transparency and GHG reporting, which can lead to misconceptions about how “green” a steel product really is.

For the purpose of this article, Nucor defines “green steel” as low-embodied carbon steel, which is explained in greater detail below.

Understanding Embodied Carbon in Steel

Embodied carbon is the amount of GHG emissions associated with the production stage of a product’s lifecycle. For steel, this includes the emissions associated with things like raw material extraction, transportation, steelmaking furnaces and equipment, and purchased electricity. Thus, a product with low-embodied carbon was produced with lower production-stage carbon emissions.

There are several methods for defining low-embodied carbon construction materials and tracking GHG emissions through a product’s lifecycle. One way to do so is for companies to develop improved data around GHG emissions using an Environmental Product Declaration (EPD). An EPD is a document that provides transparency about a product’s environmental impact using verified data and industry benchmarks to determine thresholds for types of construction materials, including steel. The Label Program Approach for identifying low embodied carbon construction materials within the Buy Clean Initiative is a system that will enable manufacturers to submit an EPD that meets the EPA’s criteria to earn the label.

The lowest-embodied carbon steel commercially available at scale is produced using electric arc furnace (EAF) technology. The EAF steelmaking process emits significantly less greenhouse gas emissions during the manufacturing process compared to the traditional blast furnace (BF) and basic oxygen furnace (BOF) steelmaking process.

- Blast Furnace / Basic Oxygen Furnace Steelmaking: Globally, most steel (about 73%) is made with BF-BOF technology at integrated steel mills. This traditional steelmaking process is highly GHG-intensive using coke, porous coal-based fuel and limestone to produce iron from iron ore that is extracted from the earth as its primary feedstock. According to Worldsteel, the global average for BF-BOF steel is 2.33 metric tons of CO₂ per metric ton of steel produced for Scopes 1, 2 and 3.

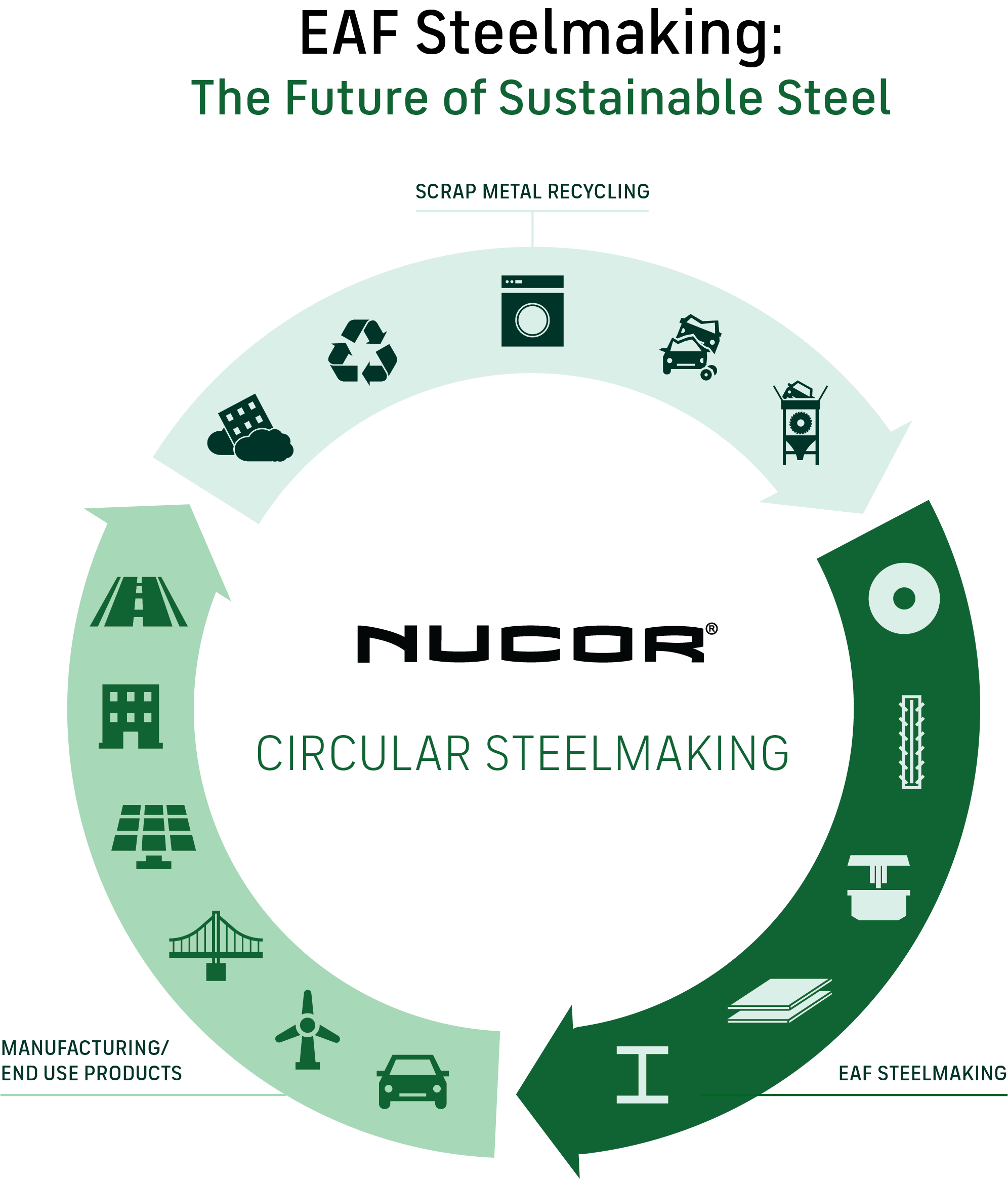

- Electric Arc Furnace (EAF) Steelmaking: Nucor uses EAF technology, a process that uses electricity to melt and recycle steel scrap – its primary feedstock – into new steel. Nucor’s EAF process yields an average of 0.77 metric tons of CO₂ per metric ton of steel produced for Scopes 1, 2 and 3. Steel is infinitely recyclable, so Nucor can continue to reuse and repurpose steel scrap into new steel products with some of the lowest embodied carbon values.

Nucor’s EAF steelmaking process produces less than one-third the GHGs compared to the global average of the traditional BF-BOF method, resulting in lower-embodied carbon steel.

To learn more about how steel is made, explore Two Ways to Make Steel: BF-BOF vs. EAF.

Defining Green Steel: Low-Embodied Carbon Steel

How do you know if the steel you purchase is truly sustainable? There are several defining characteristics of low-embodied carbon steel:

Indicators of Low-Embodied Carbon Steel:

- Manufactured using sustainable technologies like an electric arc furnace (EAF)

- Composed primarily of recycled scrap metal rather than mined raw materials

- Produced with lower-than-average GHG intensity for the global industry

- Backed by an Environmental Product Declaration (EPD)

- Complies with climate legislation requirements

Nucor is committed to being a decarbonization leader in the steel industry and helping our customers reach their sustainability goals. We base our net-zero 2050 targets on the science-based carbon emissions reduction standards of the Global Steel Climate Council.

Find out how we’re committed to building a better future: Nucor: Made for Good

The Future of Steelmaking

Steel manufacturers should adopt more sustainable technologies in steelmaking, such as the use of recycled steel and EAFs powered by carbon-free energy to produce low-embodied carbon steel. By implementing these innovations, we can reduce the steel industry’s environmental impact and meet increasing regulatory and market demands to create a net-zero future.

Benefits of Low-Embodied Carbon Steel:

- Reduction of greenhouse gas (GHG) emissions

- Decrease in steel purchasers’ Scope 3 emissions

- Produced with lower-than-average GHG intensity for the global industry

- Preservation of natural resources

- Infinitely recyclable

- Assists in meeting corporate- and project-driven sustainability & ESG goals

- Meets consumer demand for more sustainable construction materials

The future economy will be built on steel — and the steel it’s built from matters. Circular EAF steelmaking provides a bridge to meet global steel demand while minimizing environmental impact. Specifying low-embodied carbon steel in your next project is the first step toward sustainable construction.

Nucor is a North American EAF steel manufacturer with net-zero, science-based greenhouse gas targets for 2050, which includes Scopes 1, 2 and 3. We are committed to our sustainability goals by clearly defining our product emissions and we’re proud to be part of building a circular economy.

Learn more about our sustainability goals: Nucor Sustainability