Sustainable Steel 101: A Glossary of Terms You Need to Know

Navigating the lexicon of sustainability terminology can be a daunting task, especially in large-scale construction projects like high-rises, stadiums, data centers, bridges and airports. Some organizations may use terms differently with varying meanings depending on the requirements for both domestic and international projects, so you need reliable and science-based definitions that will guide your project’s sustainability goals.

Nucor is dedicated to leading with transparency, so let’s dive into the most common sustainability terms related to the steel and industrial manufacturing world. Please note that this list is not universally comprehensive, but these definitions should help you to become more familiar with foundational sustainability terminology and better understand the sustainable construction landscape.

Sustainable Terms in the Steel and Construction Industry:

- Biochar: Biochar is a stable solid, rich in carbon made from organic waste material or biomass that is partially combusted in the presence of limited oxygen. It is a lightweight black residue that can be used in steel production in electric arc furnaces (EAFs) to reduce carbon emissions and improve sustainable manufacturing processes.

- Blast Furnace (BF) / Basic Oxygen Furnace (BOF): BF-BOF technology is the more traditional way to make steel (also known as integrated or extractive steelmaking) where a type of metallurgical smelting is used to turn carbon-rich molten pig iron into new steel. It is an emissions-heavy process due to the CO₂ generated as a byproduct of the materials, melting process and the extraction of natural resources from the earth. BF-BOF steelmaking is one of the two primary ways steel is made today.

- Carbon Capture and Storage (CCS): Carbon capture and storage (CCS) is a three-step process used to remove CO₂ from the atmosphere that involves capturing the CO₂ produced by power generation or industrial activity, transporting it and then permanently storing it deep underground as a way of reducing carbon dioxide (CO₂) emissions, which helps tackle global warming.

- Carbon Footprint: A carbon footprint or a company carbon footprint (CCF) is the total amount of greenhouse gases (GHGs) generated by the activities of an individual or organization, either directly or indirectly.

- Carbon Offsets: A carbon offset (or a carbon offset credit) broadly refers to a reduction in greenhouse gas emissions (such as reforestation or methane capture projects) or an increase in carbon storage used to compensate for or balance emissions that occur elsewhere to claim GHG reduction goals.

- Carbon pollution-free electricity (CFE): Carbon pollution-free electricity (CFE) is electrical energy produced from resources that generate zero carbon emissions to the extent there is active capture and storage of CO₂ emissions for Environmental Protection Agency (EPA) requirements to support a sustainable power market. Sources of CFE include marine energy, solar, wind, hydrokinetic, geothermal, hydroelectric, nuclear, renewably sourced hydrogen and electrical energy generation from fossil fuel resources.

- Circular Economy: The circular economy is a model of resource production and consumption involving the reusing and recycling of existing materials and products as long as possible to extend their life cycle and increase sustainability. For example, recycling steel from end-of-life buildings into steel that is used to construct new buildings.

- Circular Steelmaking: Circular steelmaking, powered by electric arc furnace (EAF) technology, is a recycling-based steelmaking process that uses electricity to melt scrap metal and other inputs into new, high-quality steel. The circular steelmaking process is significantly less emissions-intensive and more sustainable than the traditional, integrated steelmaking process. By recycling scrap as a primary source of iron, the circular process keeps more carbon-rich materials in the ground – conserving natural resources – and helps to mitigate carbon emissions produced by integrated steelmaking and BF-BOF technology. EAF steelmaking is one of two primary methods for making steel today.

- Decarbonization: Decarbonization refers to the removal or reduction of carbon dioxide CO2 from a process or material.

- Electric Arc Furnace (EAF): An electric arc furnace is a furnace that heats material using an electric arc in mini-mills through a batch melting process that melts down scrap metal and other materials to produce new steel. Steel made using EAF technology produces less than one-third the carbon emissions of steel made using blast furnace (BF) / basic oxygen furnace (BOF) technology. EAFs are essential to building a circular economy and lowering greenhouse gas emissions in steelmaking.

- Embodied Carbon: Embodied carbon (or embodied GHG emissions) refers to the amount of GHG emissions associated with the upstream (extraction, production, transport and manufacturing) stages of a product’s life. Efforts are underway to reduce embodied carbon to address climate change. EAF steel is an example of a low embodied carbon steel product compared to higher embodied carbon steel made with BF-BOF steelmaking.

Environmental Product Declaration (EPD): An EPD is a third-party verified report that transparently communicates a product's impact on the environment due to its creation.

What is the environmental impact of a steel product throughout its whole lifecycle? Steel purchasers can look at the individual EPDs for their project’s steel materials to make informed decisions and meet their project sustainability goals.

Global Steel Climate Council (GSCC): The GSCC is a non-profit association created to “advance climate strategy by establishing a global standard and advocating for carbon emissions reductions by members of the steel industry”. The GSCC currently includes more than 35 international members and supporters across the steel value chain, including steel producers, upstream material and services suppliers, downstream manufacturers and end-users as well as trade associations. Nucor is a founding member of the GSCC.

The GSCC created The Steel Climate Standard, which is a science-based target to measure and report steel carbon emissions to reduce GHG emissions on a global scale for the steel industry. Nucor uses this standard to measure and set our own company GHG reduction targets, in addition to our 2030 interim target and 2050 net-zero target.

- Global Warming Potential (GWP): According to the Environmental Protection Agency (EPA), GWP is “a measure of how much energy the emissions of one (1) ton of a gas will absorb over a given period of time, relative to the emissions of one (1) ton of carbon dioxide (CO₂)” (EPA.gov).

- Greenhouse Gasses (GHG): Greenhouse gases consist of carbon dioxide, methane, ozone, nitrous oxide, chlorofluorocarbons and water vapor. GHG emissions become trapped in the earth’s surface and increase the temperature of the planet, resulting in global warming.

- Integrated / Extractive Steelmaking: The integrated steelmaking process, also known as extractive steelmaking, is the traditional method for producing steel. It starts with mining raw materials out of the ground, including iron ore, limestone and coal. These materials are melted in a blast furnace (BF), which reacts with iron oxide and carbon (in the form of coke, a porous coal-based fuel) to form two products: iron (saturated with carbon) and CO₂. Liquid iron from the blast furnace is then reacted with oxygen in a second step via a basic oxygen furnace (BOF) to remove excess carbon, producing even more CO₂. This reduced form of iron is steel and is highly carbon-emissions intensive compared to steel made with an EAF.

- International Standards Organization (ISO): ISO is an independent, non-governmental, international standard development organization composed of representatives from the national standards organizations of member countries to ensure that the products and services you use daily are safe, reliable, and of high quality. ISO standards in the steel industry help companies maintain or exceed certifications, including the ISO 14001: 2015 for environmental management system (EMS).

- Ladle Metallurgy Furnace (LMF): A Ladle Metallurgy Furnace, also called ladle refining or secondary steelmaking, is a furnace that refines molten steel into specialty grades after it has moved through the electric arc furnace (EAF). The functions of the LMF include: 1) Control gasses, 2) Desulfurize, 3) Remove undesirable non-metallics, 4) Modify inclusions and 5) Alloy additions.

- Life Cycle Assessment (LCA): A life-cycle assessment (LCA) is a comprehensive method of evaluating the potential environmental impacts of a product, material, process or activity. It is used to assess a range of environmental impacts across the full life cycle of a product system, from the acquiring of materials to manufacturing, use and final disposal. Since steel is infinitely recyclable, scrap from end-of-life products can go back into (EAF) steel mills to be melted down and recycled. Environmental Product Declarations (EPDs) summarize the results of an LCA for a specific product that helps track lifecycle emissions.

Low-Embodied Carbon Steel: Embodied carbon is the greenhouse gas emissions associated with the upstream stage of a product’s lifecycle – raw materials, manufacturing, and transport – also known as cradle-to-gate. Low-embodied carbon steel is steel produced with low cradle-to-gate carbon emissions.

Low-embodied carbon steel is produced using an electric arc furnace which emits significantly less greenhouse gases during the steel manufacturing process, compared to extractive steelmaking with BF-BOF technology. While “green steel” is a commonly used generic term, “low-embodied carbon steel” is the industry-acceptedterm and provides more transparency and context when evaluating project sustainability targets.

- Mini-Mill: mini-mill refers to a steel mill that uses an electric arc furnace for scrap melting and conversion into new steel, creating a circular process. With advancements in EAF technology, mini-mills are efficient and capable of higher output for all types of steel.

- Net Zero: Net zero refers to “a state in which the greenhouse gases going into the atmosphere are balanced by removal out of the atmosphere. The term net zero is important because – for CO₂ at least – this is the state at which global warming stops” (Net Zero Climate).

Nucor’s net-zero low-embodied carbon steel at scale is Econiq™, which certifies that your steel or steel products were made with 100% emission-free and/or renewable electricity. The Econiq certification can be applied to all of Nucor’s steel and fabricated steel products.

- Nuclear Fission: Nuclear fission is a conventional kind of carbon-free technology that occurs when a neutron collides with a uranium atom and splits it, releasing a large amount of energy in the form of heat and radiation. The collision causes more neutrons to be released, which continue to collide with other uranium atoms, and the process repeats itself.

-

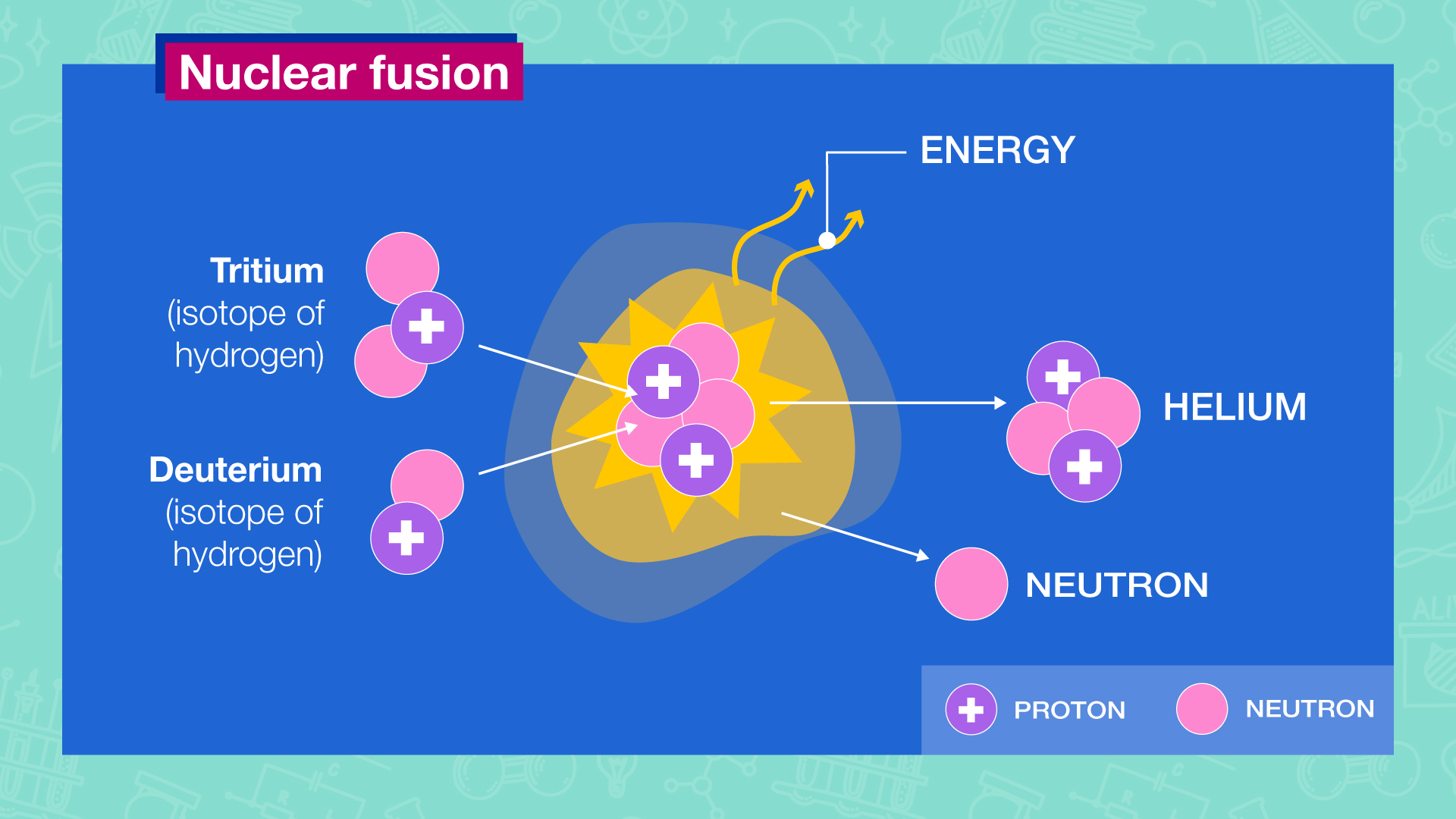

Nuclear Fusion: Nuclear fusion is the process by which two light atomic nuclei combine to form a single heavier one, resulting in the release of massive amounts of energy. The sun is powered by this process, and if nuclear fusion could be replicated industrially on earth, it could provide limitless safe, clean and affordable energy to sustainably meet the world’s demand. For example, fusion could generate nearly four million times more energy than burning oil or coal.

Paris Agreement: The Paris Agreement is a legally binding international treaty that was initiated on November 4, 2016 with an overarching goal to support efforts to limit the global warming temperature increase to 1.5°C above pre-industrial levels . As of 2024, 195 Parties (194 States plus the European Union) have joined the Paris Agreement, which includes commitments from all countries to reduce their emissions and work together to adapt to the impacts of climate change and strengthen their commitments over time. It also creates a pathway for developed nations to assist developing nations in their climate mitigation and adaptation efforts and create a framework for the transparent monitoring and reporting of countries’ climate goals. The Paris Agreement provides a foundation for a net-zero emissions world.

When buying steel – even steel made in the US – steel purchasers need to be aware that the type of steel they purchase matters. Steel purchasers can make play a role in emissions reductions by choosing circular steel made with an (EAF). Many companies like Nucor have set carbon emissions goals to align with and even exceed the Paris Agreement standards to build a net-zero circular economy.

- Product Category Rule (PCR): PCRs are used to prepare Environmental Product Declarations (EPDs) for steel and other products sold or used in North America, which support the initiative to increase low embodied carbon construction materials.

- Renewable Energy Certificate (REC): “A renewable energy certificate, or REC (pronounced: rěk, like wreck), is a market-based instrument that represents the property rights to the environmental, social and other non-power attributes of renewable electricity generation. RECs are issued when one megawatt-hour (MWh) of electricity is generated and delivered to the electricity grid from a renewable energy resource” (EPA.gov).

- Science Based Targets Initiative (SBTI): The SBTI uses science-based targets to show businesses how much and how quickly they need to reduce their GHG emissions to prevent the worst effects of climate change.

Scope 1, 2 and 3 Emissions: Developed by the Greenhouse Gas Protocol, Scopes 1, 2 and 3 give organizations a way to categorize their emissions. Generally, Scope 3 is the most inclusive category and hardest to reduce.

- Scope 1 Emissions: The direct emissions generated by an organization's operations, like running machinery, manufacturing products, driving vehicles and other operational activities that generate emissions.

- Scope 2 Emissions: The indirect emissions generated by an organization's energy purchase and usage. Investment in renewable energy sources may help lower these emissions. For example, a company that gets their electricity via renewable energy sources like solar and wind have a lower Scope 2 than a company whose grid is supplied by fossil fuel power generation.

- Scope 3 Emissions: The indirect emissions generated by an organization's downstream customer and supplier activities. This is likely to be the largest share of your carbon emissions. Examples include employee commutes, transportation and shipping of materials, waste generated in daily operations, etc.

- Supply Chain Traceability: Supply chain traceability is the ability to track and document the movement of goods throughout the supply chain that provides a foundation of data availability and transparency so that an organization can accurately report its ESG, or environmental footprint, social impact and governance (compliance with laws and regulations).

Sustainability: Sustainability is the principle of creating and maintaining environmental conditions so that humans and nature can coexist to support current and future generations. It revolves around preserving the environment and natural resources without causing depletion or permanent damage.

Sustainability has many expressions across industries and stakeholders. For Nucor, sustainability is expressed as decarbonization and circularity. In recent years, sustainability has become a differentiator for steel purchasers when evaluating building materials for projects especially with the introduction of local, state and national legislation, regulations and organization-wide sustainability and carbon emission goals.

- Whole Building LCA (WBLCA): WBLCA is a holistic way to measure embodied carbon and other environmental impact measures associated with buildings by studying the totality of products present in a building and providing valuable information for decision-making related to the design, construction, operation, maintenance and eventual demolition or reuse of a building.

- World Steel Association (abbrev. worldsteel): worldsteel is one of the largest and most dynamic industry associations in the world, with members in every major steel-producing country. worldsteel represents steel producers, national and regional steel industry associations, and steel research institutes. Members represent around 85% of global steel production.

worldsteel has five main activity focus areas:

- Promote safe and healthy working conditions in the steel industry.

- Promote the image of steel as an industry and as a material.

- Develop a global response to the environmental challenge.

- Focus on understanding and shaping megatrends that could influence the sustainability of the steel industry.

- Align activities with national & regional associations.

In 2023, Nucor announced a collaboration with Helion, a fusion power company, to develop a 500 MW fusion power plant with the purpose of producing zero-carbon baseload electricity from fusion to power a Nucor EAF steelmaking facility. This is the first fusion energy agreement of this scale in the world and could pave the way for decarbonizing the entire industrial sector.

Nucor is committed to transparency in GHG emissions reporting and continues to invest in new sustainable products, resources and capabilities to meet both current and emerging market needs as we continue to expand the circular steel economy. We serve as your strategic partner by applying the latest innovations, staying at the forefront of design trends and using market analytics to develop products and solutions to solve your complex challenges.

Learn more about Nucor’s sustainability targets: Net Zero by 2050