Driving Toward a Sustainable Future

Nucor is accelerating the transition to more sustainable automotive production through our sustainable steel bar and sheet products, wide variety of grades and technical expertise.

Download Product GuideCircularity

Nucor uses circular, electric arc furnace (EAF) steelmaking to create sustainable automotive steel products.

Reliable Supply Chain

With North America’s largest network of EAF steel mills, Nucor has the capabilities to accelerate the steel supply chain.

Partnership

We serve as your collaborative partner from platform design and material development to technical support.

The above video has no voiceover. It contains wide shots of Nucor's products and a label foreach one.

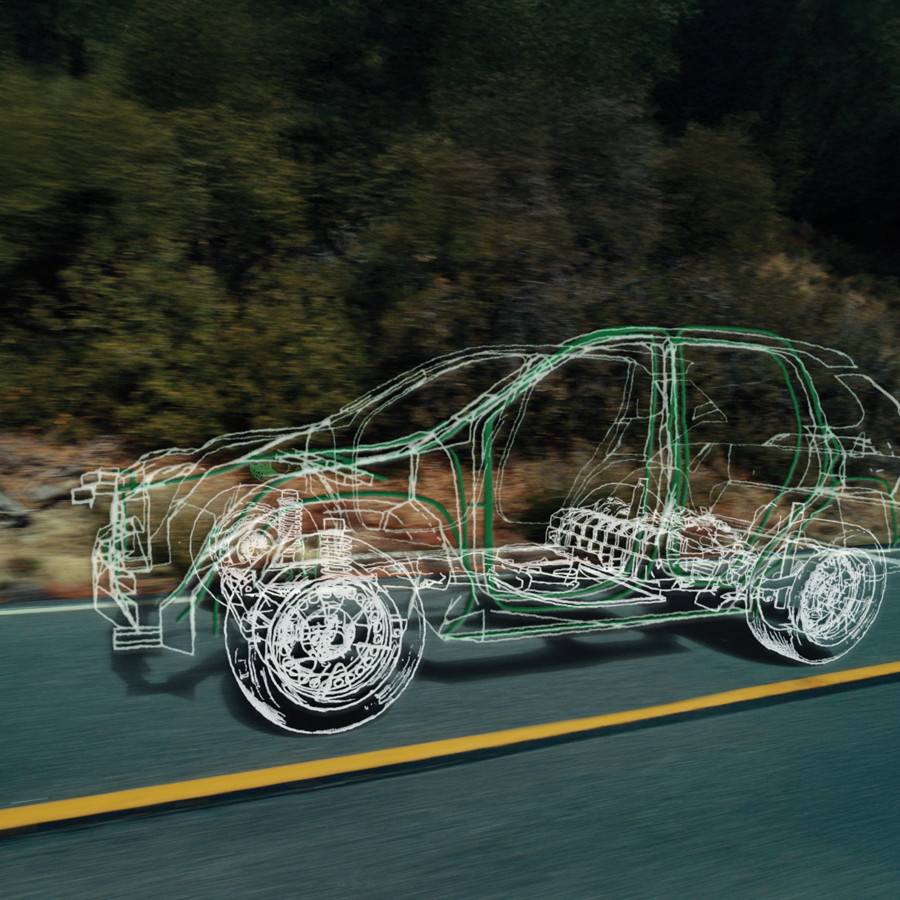

Where You’ll

Find Our Steel

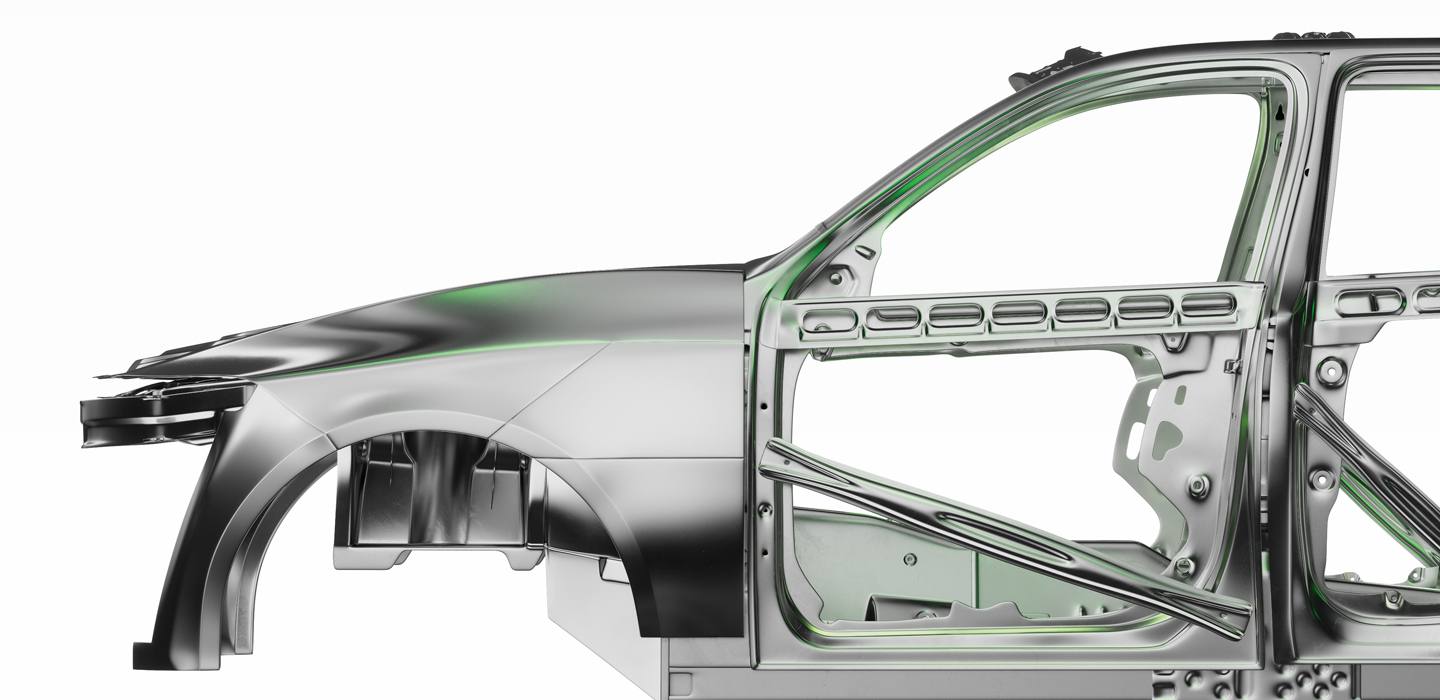

One partner for a wide breadth of multi-point solutions

Our high-strength steel sheet and engineered bar products are used in a wide range of automotive applications for internal combustion engine (ICE) and electrified vehicle (EV) platforms.

Toggle between internal combustion and electric vehicles

Accelerating innovation in the auto industry

Certified Green Steel at Scale

Steel at Scale

Econiq™ is the world’s first net-zero carbon steel at scale and a certified low-embodied carbon steel solution for automotive applications. Econiq provides steel purchasers a broad portfolio of certified products to achieve their sustainability goals.

Leading Decarbonization

Decarbonization

Our circular steelmaking process produces greenhouse gas emission (GHG) intensity that is less than half the global average for extractive, blast furnace steelmaking for Scopes 1, 2 and 3.

Infinite Recycling

Recycling

Nucor is the largest recycler in North America. Our steel products are made with an average recycled scrap content of 77.3%, much coming from the automotive industry. Steel can be infinitely recycled with no loss in quality.

Nucor offers steel innovations and services across industries

Auto/Steel

Auto/Steel

Parnership

As proud members of the Auto/Steel Partnership, we work alongside other manufacturers, leveraging the latest research to meet the challenges the auto industry faces today and exceed the demands of tomorrow.