Together with our partners, we’re leading the charge to create a more sustainable future.

Let's ChatMade for Good

Automaker Case Study

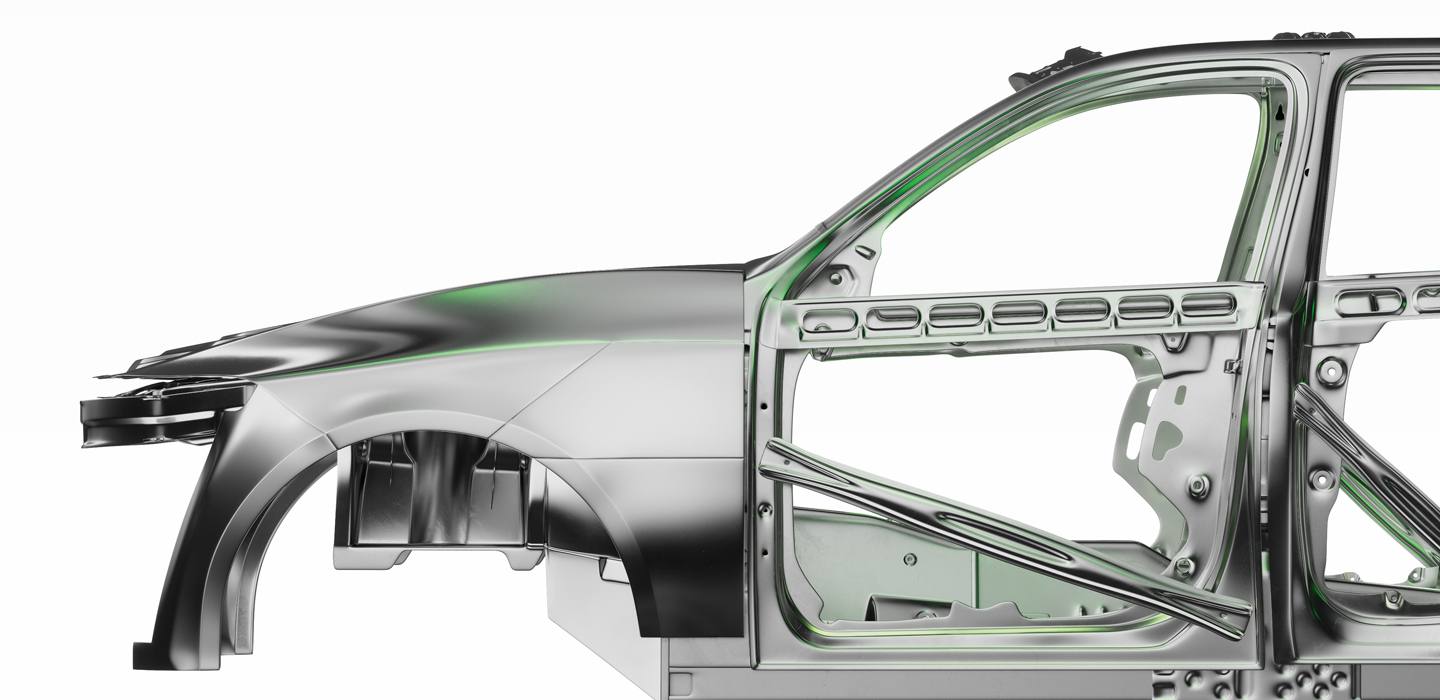

Lowering An Automobile's Environmental Impact before its first mile

A major auto manufacturer partnered with Nucor to produce its first luxury electric vehicle with Econiq™ net-zero carbon steel, significantly reducing Scope 3 emissions and bringing the manufacturer closer to its goal of carbon neutrality by 2040.

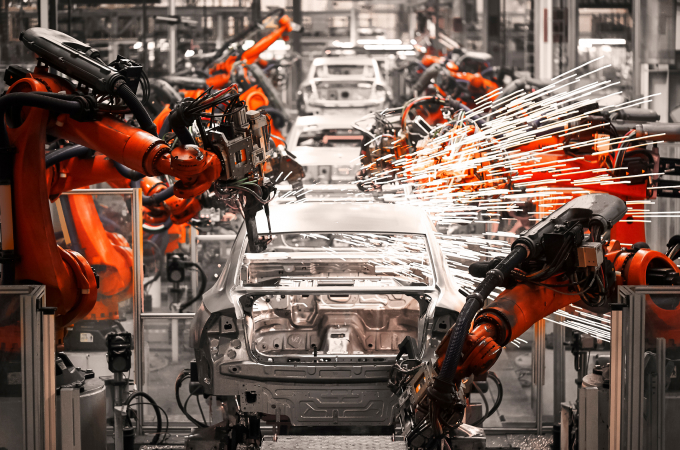

Road vehicles account for nearly 15% of total global CO2 emissions today and are the fastest-growing source of emissions worldwide. With both traditional and electrified vehicle production accelerating, the auto industry is looking for ways to rapidly decarbonize its supply chains to meet current and future sustainability goals

But what if we could lower a vehicle’s carbon footprint before it was ever driven? And what if the sustainable cars of the future could be built with circular steel from the past?

In 2021, one Nucor customer — a major auto manufacturer — led the charge for comprehensive decarbonization. As a signatory of the UN’s Business Ambition Pledge for 1.5°C, the automaker challenged itself to reach a series of ambitious sustainability goals, including a significant reduction in Scope 3 emissions from its vehicle production by 2035, and a commitment to achieving carbon neutrality in its products and operations by 2040.

In order to help companies like this meet their sustainability goals, Nucor launched Econiq™, the world’s first net-zero carbon steel at scale and a certified low-embodied carbon steel solution. The Econiq certification can be applied to any product from Nucor’s steel mills and signifies that the product has been produced using electricity from 100% renewable sources (eliminating Scope 2 emissions) and by purchasing carbon offsets (eliminating Scope 1 emissions).

Additionally, Nucor’s modern steelmaking process relies on circular electric arc furnace (EAF) technology. EAF steelmaking uses recycled scrap as its primary feedstock to make new steel, resulting in a truly circular product. Nucor is a leading pioneer in this circular process, which has an emissions intensity that is less than one-third the global average of extractive steelmaking.

ECONIQ™

THE FIRST NET-ZERO CARBON STEEL AT SCALE FOR THE AUTO INDUSTRY

- Produced using energy from 100% renewable sources, eliminating Scope 2 emissions

- Scope 1 emissions are eliminated via carbon offsets

- Most comprehensive net-zero carbon steel product line in the US market

- Certification is available on all Nucor products

Nucor's goals are closely aligned with our customers’ goals, and we continue to work in partnership on new opportunities and innovations like Econiq.

Director, Nucor Automotive Solutions