Together with our partners, we’re leading the charge to create a more sustainable future.

Let's ChatMade for Good

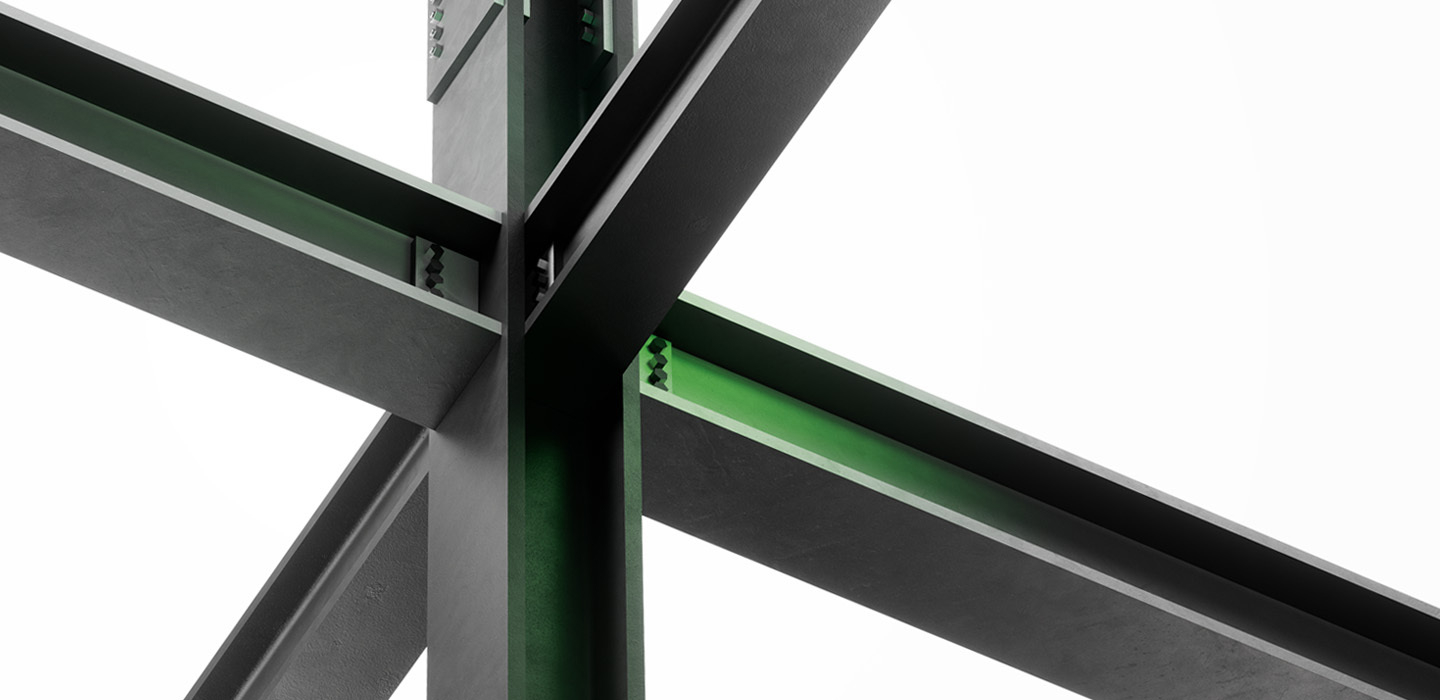

Construction Case Study

CAN WE SUPPORT STRONGER STRUCTURES WITH LESS Steel?

Nucor partnered with Turner Construction Company, Banker Steel, and NYC Constructors to develop, fabricate, and erect a creative approach to the building’s structural components using Aeos™ A913 steel.

Rising along the Manhattan waterfront is a new 66 story office tower known as “The Spiral.” Located in the Hudson Yards neighborhood at the intersection of the High Line and Bella Abzug Park, The Spiral is named for a cascade of terraces that wind their way around the building’s facade, creating one continuous green pathway “from the Highline to the skyline.”

Developed by Tishman Speyer and designed by architects at Bjarke Ingels Group and structural engineers at WSP USA, The Spiral sets a new standard for sustainable architecture in New York City through this unprecedented integration of the natural and built environments and a focus on environmental considerations in its construction and ongoing operations.

This ambition is reflected in the building’s LEED Gold certification, but the path there was not always straightforward. One implication of the building’s unique, spiraling design is that each of its 66 stories has a distinct floor plan, requiring significant material and engineering innovation to bring the structure to life.

Aeos is a sustainable, high-strength structural steel that features superior weldability and toughness, backed by a team of collaborative experts from Nucor Construction Solutions. The product’s high strength-to-weight ratio and flexibility enabled an economy of material that made it uniquely suited to solving the Spiral’s complex engineering and sustainability challenges.

By reducing the overall quantity of steel required to build The Spiral, the project team avoided thousands of tons of greenhouse gas (GHG) emissions. Fewer perimeter columns and smaller column sizes also translated into improved interiors with more usable space for tenants, a key component of The Spiral’s biophilic design. As Nucor is the only domestic provider of A913, building with Aeos created the opportunity to further reduce emissions relative to imported alternatives.

MINIMIZING CARBON, MAXIMIZING DESIGN

- Aeos™ is the only domestically produced A913 material

- Made of 95% recycled content

- 15-25% column weight savings (when compared with A992)

- 65% smaller column footprint, increasing interior square footage

- Greenhouse gas (GHG) intensity less than 1/3 the global extractive steelmaking average using blast furnaces for Scope 1, 2, and 3 emissions

- Can be certified Econiq™ for further reduced GHG intensity

The benefit from having higher-strength, lighter material, [is] less effort in the fabrication process and less impact on the environment.

Executive Vice President & Managing Director, Building Structures at WSP USA

Aeos is as sustainable as it is strong. The product contains 95% recycled content and is made using Nucor's circular, electric arc furnace (EAF) manufacturing process. Nucor is a leading pioneer in this recycling-based process, which has an emissions intensity that is less than one-third the global average of extractive steelmaking methods using blast furnaces for Scope 1, 2 and 3 emissions.

Like all Nucor steel, Aeos can also be certified Econiq™ signifying that it was produced using electricity from 100% renewable sources (eliminating Scope 2 emissions), with the option to offset any remaining Scope 1 emissions.

Building the green economy of the future means choosing sustainable solutions today. As new tenants flood into The Spiral’s forward-thinking office space, the building’s groundbreaking design, enabled by Aeos, highlights new possibilities for sustainable architecture.