EPDs in Steel 101: What is an Environmental Product Declaration (EPD)?

Environmental Product Declarations (EPDs) in Steel: Part 1

Do you have the tools you need to report the environmental impact of construction materials used for your project? Transparency is vital in selecting materials as the construction industry moves toward more sustainable structures and how those materials meet project sustainability goals along with legislative and regulatory requirements.

How do engineers, designers and other industry professionals prepare for projects with strict embodied carbon requirements? Look for products with environmental product declarations, or EPDs.

In this introductory article in the EPDs in Steel series, we will look at what an EPD is and why it matters for your construction project.

What is an Environmental Product Declaration?

An environmental product declaration (EPD) is a document that provides transparent information about a product's environmental impact throughout its lifecycle.

An EPD is like a nutrition label, outlining a product’s impact on the environment — it requires one year of production data to be used within a life-cycle assessment (LCA), ultimately creating the product’s environmental impacts in six categories.

EPDs are based on international standards and product-specific guidance to ensure consistent and transparent environmental data based on a framework that makes it possible for readers to understand the results in the report.

How to Create an EPD

The backbone of an EPD is a life cycle assessment, or an LCA, which is a systematic method used to quantify and evaluate a product’s environmental impact throughout its life. The primary inputs into an LCA are 12 months of consecutive production data, used alongside datasets outlining the environmental impacts of each input and process to make a product. The summation of each of these individual processes and materials will then be summarized within the EPD within six standardized impact categories.

The other foundational element of an EPD is a Product Category Rule (PCR), which is a material-specific guidance that defines the information or scope that must be gathered and evaluated to create the EPD. For steel, the PCR is the “North American Product Category Rule for Designated Steel Construction Products,” with Version 1 released in 2015, Version 2 in 2018 and Version 3 currently under review.

The EPD process follows the International Organization for Standardization (ISO), which governs information included in the final document to ensure consistency. ISO 14025, “Environmental labels and declarations” and ISO 21930, “Sustainability in building construction” are the two primary governing standards for construction material EPDs.

A three-part team must be established to publish the final public-facing EPD document, which consists of the following entities:

- A product owner (or study commissioner) is typically the manufacturer, an organization that produces the product and uses an EPD to provide transparent environmental impact.

- A practitioner is a consultant who uses LCA model software to calculate product information for the EPD.

- A program operator is an unbiased third party that verifies the accuracy of the data and all information in the background report of the EPD and ensures compliance with ISO standards.

As a practical example of an EPD for a steel product, Nucor would be the product owner as the manufacturer, they would work with a consultant as the practitioner and a third-party program operator to ensure compliance with standards.

Knowing the process of how an EPD is made helps manufacturers, designers and engineers verify that the data is accurate, standardized and compliant with international standards to ensure transparency. This knowledge allows professionals to make informed decisions about material selection, helping them meet sustainability goals and regulatory requirements while minimizing the overall carbon footprint of their projects.

Categories of EPDs: Verification, Type and Scope

After understanding what makes up an EPD, it's important to explore the key categories that define it, which will further clarify the information provided in the final EPD documentation.

1. EPD VerificationsFirst, EPDs are classified into two types of verifications, which are important to clarify for sustainability assessments.

- Type II EPDs: self-declaredType II EPDs are environmental claims made by manufacturers or other product owners. They don’t require third-party verification and can include information about specific environmental attributes of a product, such as recycled content or energy savings. While Type II EPDs can provide valuable insight into a product’s environmental benefits, they are not third-party verified, which limits their credibility.

- Type III EPDs: third-party verifiedType III EPDs are more rigorous and follow standardized guidelines set by ISO and product category rules as described above. Type III EPDs require third-party verification and include an analysis of the product’s lifecycle environmental impacts, such as global warming potential, energy use and water consumption. These declarations are based on a detailed LCA and offer a transparent and reliable declaration. If a customer requires an EPD for a construction project, it typically must be a Type III verified EPD to meet project requirements.

2. EPD TypesIn addition to verification, there are three main types of EPDs that can be created.

- Industry-Average EPD An industry average EPD outlines the aggregated environmental impact of a specific product within a particular industry, using production data from multiple producers or manufacturers in the same sector. These types of EPDs are commonly developed by trade organizations or industry associations such as AISC, CRSI, SJI and SDI within the steel industry. The purpose of this type of EPD is to provide a general baseline of the environmental performance of a specific product, represented by the majority of the producers within that market.

- Product-specific EPDThese measure the environmental impact results of one specific product made by one company or manufacturer, which could be produced in multiple facility locations. This type of EPD would be created by a material manufacturer, such as Nucor, and provides a higher level of precision and transparency, as more specific production data is needed. These types of EPDs are generally used during procurement or refining a project’s sustainability targets.

- Facility-Specific EPDThis type of EPD captures the unique environmental performance of a product made at one production site, considering factors such as energy usage, emissions and waste generation specific to that location. This information allows manufacturers to highlight improvements in sustainability at designated production sites, particularly when different facilities have varying environmental performances. For projects that prioritize transparency and local impact, facility-specific EPDs offer insight into the localized effects of production and help in making more informed, site-sensitive decisions.

For example, an industry average EPD would provide the environmental impact of steel wide-flange sections based on data collected from multiple manufacturers across the industry, offering a general benchmark. A product-specific EPD would detail the environmental impacts of that type of steel made by one manufacturer, and a facility-specific EPD would focus on the environmental performance of that steel produced at a single manufacturing site, taking into account the unique conditions and processes of that specific facility.

3. EPD ScopeThe final category to differentiate types of information in an EPD is the scope, which determines whether it covers the entire lifecycle of the product or just specific stages.

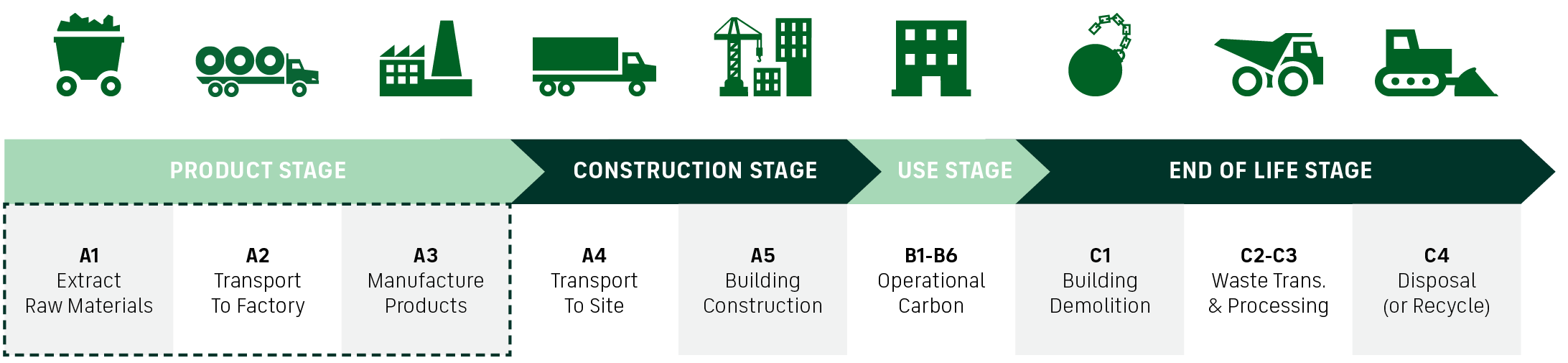

- Cradle-to-Gate EPDsThis category of EPD covers the environmental impact of a product from raw material extraction or scrap processing (the cradle) to the point it leaves the manufacturer (the gate), also known as stages A1-A3 . These boundaries are clearly defined within the PCR and enable manufacturers to provide primary data, as they are often in direct control of each step within these stages.

- Cradle-to-Grave EPDsThese EPDs provide a full lifecycle analysis of the product, covering every stage from raw material extraction through end-of-life disposal. Cradle-to-grave EPDs often come with assumptions of use and disposal stages as it’s difficult to objectively determine what will happen to a product at each stage after it leaves the manufacturing facility.

For instance, for an EPD of a car, cradle-to-gate would be its environmental impact until it leaves the manufacturing facility, whereas cradle-to-grave would be until it reaches the end of its useful life, which could vary widely depending on many factors (whether an owner has regular maintenance performed, how and what environment the car is driven within, how long the car stays on the road, if the car is properly disposed of at the end of its life, etc.).

Stages within a lifecycle assessment enable steel industry professionals to calculate EPDs.

Why EPDs Matter for Your Project

EPDs matter for construction professionals because they provide data-driven, standardized information about the environmental impacts of materials. By utilizing Type III EPDs, you can make informed decisions that align with sustainability goals and regulatory requirements. This will ensure your project meets requirements and allows you to select options that meet performance criteria and contribute to a more sustainable built environment.

Nucor is dedicated to transparency in our manufacturing processes because it reflects our commitment to sustainability. By openly sharing accurate data through tools like environmental product declarations, we empower customers to make informed decisions that align with their sustainability goals, foster accountability and drive continuous improvement. Find information about our environmental standards and EPDs here: Nucor EPDs.

Now that you understand what an EPD is, you can learn how to read an EPD effectively: EPDs in Steel Part 2

Have questions about sustainability for an upcoming project? Reach out to Nucor’s team of specialists today!

Contact Us