Together with our partners, we’re leading the charge to create a more sustainable future.

Let's ChatMade for Good

ADVANCED MATERIAL RECOVERY CASE STUDY

MODERNIZING OUR ELECTRIC GRID BY IMPROVING OUR MATERIAL RECOVERY STRATEGIES

Today’s demand for energy is extraordinary and expected to continue rising. The rapid growth of data centers, reshoring manufacturing operations and electrification of transportation has accelerated the market demands for electricity. Rethinking how industries use, and re-use materials is central to both the future of the electrified world and the work of Nucor, North America’s largest steel manufacturer and recycler.

America is at a critical energy inflection point—with national electricity demand expected to increase over 15% by 20291 and 70% of the electric grid being over 25 years old2, the need to modernize the country’s electrical infrastructure is pressing.

As North America’s largest steelmaker and recycler, Nucor uses circular, electric arc furnace (EAF) steelmaking technology to recycle old, reclaimed steel at the end of its usable life into new steel. Nucor has helped utility companies advance the nation’s energy infrastructure with one of the most sustainable and reliable domestic steel supplies in the nation, including tapered tubular steel transmission poles, light duty poles, and substation structures—all custom engineered to meet specific utility needs.

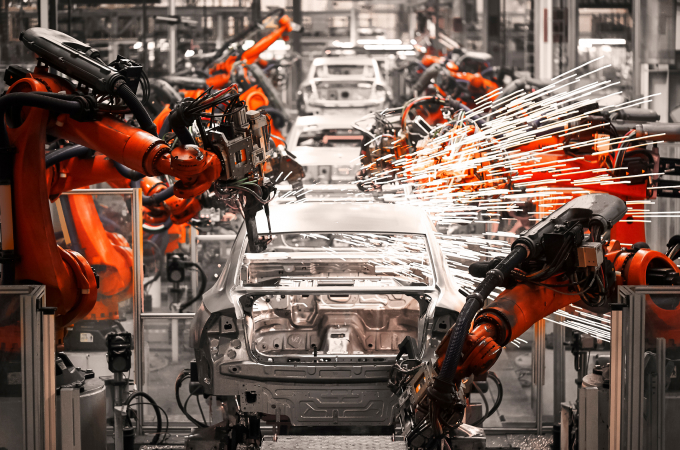

Nucor’s commitment to helping modernize the electric grid goes beyond our development and production of sustainable steel. We are continually leveraging our industrial-scale recycling expertise to explore new and innovative approaches to recover materials that are essential across key industries, from energy and automotive, to data centers and defense.

PIONEERING ADVANCED MATERIAL RECOVERY METHODS

The growing demand for electricity comes with a corresponding demand for non-ferrous metals such as copper, aluminum and titanium. Typically, these materials are sourced overseas, but Nucor is pioneering advanced material recovery processes to create a more circular, domestic supply chain for these critical inputs.

At Nucor’s advanced metals recycling facility in Bushnell, Florida, our engineers have repurposed mining equipment to create an innovative recovery method that better separates and reclaims copper and other non-ferrous metals from conventional scrap.

With this improved ability to remove more essential materials from the waste stream, Nucor is even reopening landfills to further recapture and reprocess materials once thought to be lost and unsalvageable.

AMERICA’S ENERGY INFRASTRUCTURE BUILT WITH AMERICAN-MADE STEEL

- Nucor products meet power transmission specifications, supporting up to 765kV.

- In addition to our Hazleton, Pennsylvania transmission tower manufacturing site, Nucor is building two state-of-the-art greenfield locations in Alabama and Indiana.

- We aim to meet or exceed industry standards by providing efficient project designs, tailored engineering and always delivering superior products on time.

We pioneered the circular steelmaking process in North America over 50 years ago. Today, we're taking that expertise and expanding it to other materials, advancing a more circular and sustainable future.

General Manager, Energy Solutions

In addition to current material reclamation efforts like those happening in our Bushnell facility, Nucor is continually exploring new ways to reduce industrial waste and give critical scrap materials a new life. We are partnering with our customers across major industries, including construction, automotive,

technology and advanced manufacturing to build circular steel supply chains and create new systems to recover materials at end-of-life.