Need More Info?

For additional documentation such as certifications, roll schedules and product specifications, visit us at NucorNow.

Visit NucorNow

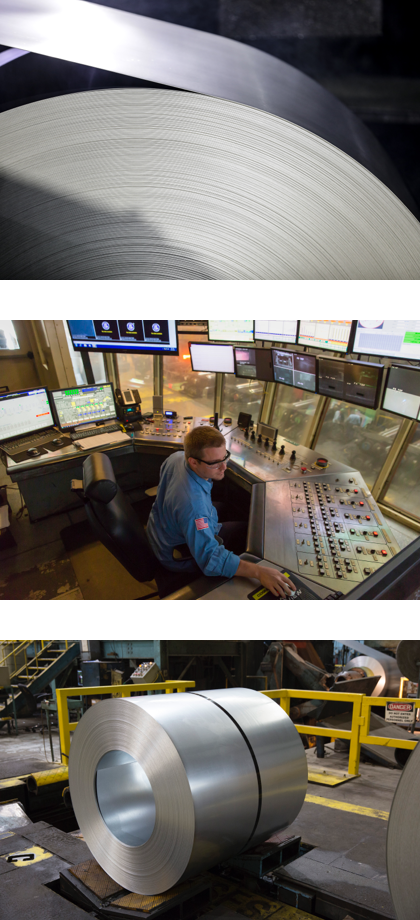

In 1989, Nucor pioneered EAF thin-slab casting at our Crawfordsville, Indiana sheet mill. Since this breakthrough, we have become the market leader by continuing to invest in advanced sheet steel products and technologies.

Today, Nucor operates six strategically located sheet mills in Alabama, Arkansas, Indiana, Kentucky and South Carolina that utilize thin slab casters to produce flat-rolled steel for automotive, appliance, construction, pipe and tube and many other industrial and consumer applications. Our sheet mill capacity is approximately 12.1 million tons per year. We produce hot rolled, cold rolled, Surestride® floor plate, galvanized and galvannealed sheet.

Our sheet mill network is both geographically diverse as well as strategically positioned near rail, highway and major seaports, ensuring secure access to products and efficient delivery timeframes throughout North America.

Learn more

Nucor’s sheet mill family includes five EAF mills that utilize thin-slab casting. Four of our EAF sheet mills are equipped with cold rolling mills and five have galvanizing lines for the further processing of hot-rolled sheet.

Through strategic investments and continuous process improvement efforts at our existing facilities, Nucor continues to greatly expand our sheet product capabilities and offerings, including producing thinner high-strength steel grades to facilitate the development of advanced applications, including lightweight automotive.

Notably, Nucor Steel Berkeley, located near the Port of Charleston, South Carolina, was the first CSP mini mill in the world to produce deep drawing steels using vacuum tank degasser technology. This mill has led the way for CSP mini mills in the development of Advanced High Strength Steel (AHSS) for the automotive industry.

In addition, our specialty cold mill complex in Arkansas has greatly expanded Nucor’s capabilities to cold reduce steel to lighter gauges and higher strengths to meet our customers’ light weighting goals. This mill also has a batch anneal shop that allows for the production of motor lamination steels with electrical properties previously only attainable by non-oriented silicon steels.

Finally, a new galvanizing facility at our mill in Ghent, Kentucky is the first of its kind in North America, coupling a pickle line directly with a galvanizing line. By the end of 2021, an additional 1.4 million tons of melting capacity will be added to this mill.

For additional documentation such as certifications, roll schedules and product specifications, visit us at NucorNow.

Visit NucorNow