Steel Construction Emissions Reporting: Linking A1-A3 and Scope 1-3 Emissions

Assessing the environmental impact of construction materials is essential for making project decisions. For steel purchasers, structural engineers, architects and fabricators, the life cycle of construction materials and processes can significantly impact project outcomes, such as lowering carbon footprints and fulfilling regulatory requirements.

Although the sustainability reporting process can be complex, you can make informed decisions by understanding the foundational elements — product lifecycle stages and emission categories.

Lifecycle Assessment: The Foundation of Understanding Environmental Impact

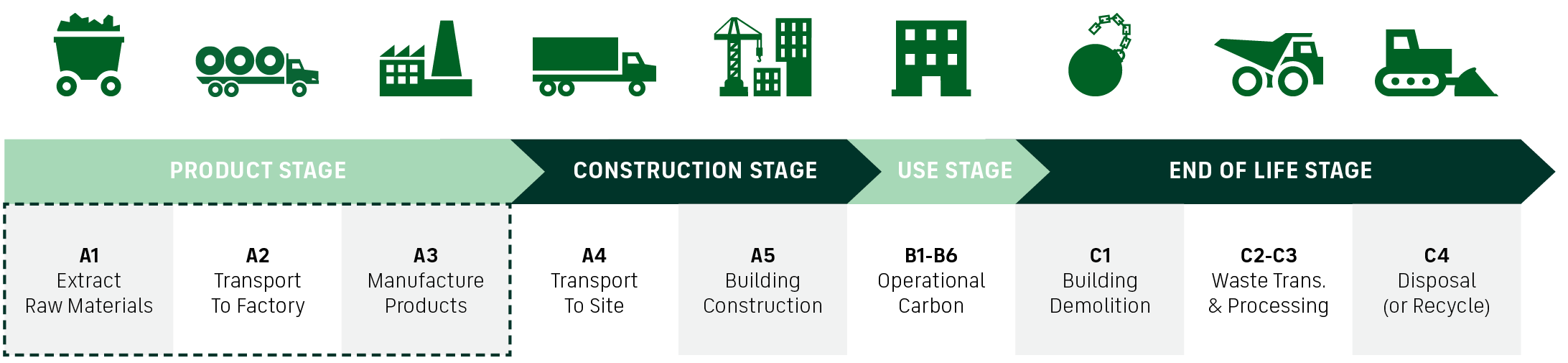

A key tool for evaluating steel products’ environmental impacts is the lifecycle assessment (LCA), which evaluates a product’s environmental impact throughout every phase of its life cycle, including the product stage (A1-A3), the construction phase (A4-A5), the use stage (B1-B6) and the end-of-life stage (C1-C4).

The LCA data is compiled to evaluate a building's environmental impact, often considering its entire life cycle, including the end-of-life phase (also known as a cradle-to-grave assessment). However, determining full-cycle LCA data can be challenging for specific building products because of subjective factors such as regional differences in manufacturing and use, variations in data quality, availability of data and other context-specific variables.

Therefore, steel manufacturers typically focus on evaluating the product stages (phases A1-A3 or cradle-to-gate), where they have complete and accurate data, allowing for more reliable assessments. This information can be used to develop product-specific environmental product declarations (EPDs) to report the environmental impact of steel.

Read more about EPDs here: What is An Environmental Product Declaration?

A1-A3: Measuring the Product Stage of Steel Manufacturing

The product stage (also referred to as cradle-to-gate) is a critical focus area within the LCA for steel products. This stage encompasses the environmental impacts of producing a specific steel product, starting from raw materials to when the product leaves the steel mill for fabrication or other uses.

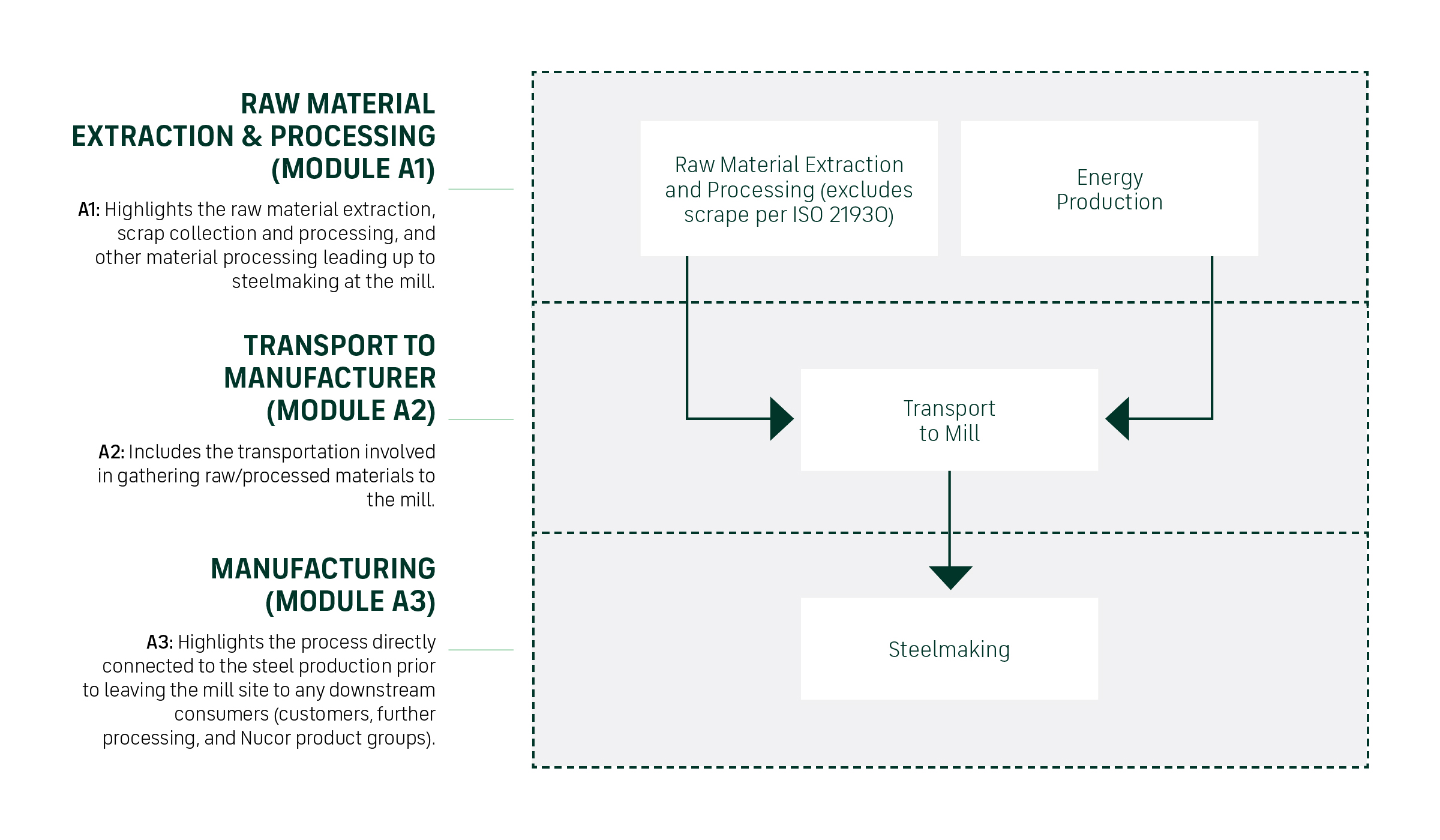

The cradle-to-gate product stage includes three key modules: A1 (raw material supply), A2 (transportation) and A3 (manufacturing). Together, these stages provide a comprehensive view of the environmental production impacts, which is essential for construction professionals who want to make sustainable material choices.

A1: Raw Material Supply

A1 focuses on the sourcing and processing of raw materials. Since there are two ways to make steel, this phase involves either using recycled scrap metal (for EAF steelmaking processes) or mined resources like iron ore (for BF-BOF processes).

The A1 stage accounts for the energy and emissions involved in material supply or extraction, refining and preparation. If you’re examining the overall impact of steel, understanding A1 is crucial because it highlights the initial carbon footprint of the material and the benefits of using scrap metal as the primary input for new steel in terms of low-embodied carbon values.

For example, Nucor’s steel made using EAF technology produces on average less than one-third the carbon emissions compared to the global average of for steel made using the BF-BOF method, largely due to its scrap metal inputs in stage A1.

A2: Transportation

The A2 stage measures the environmental impact of transporting raw materials to manufacturing facilities. This includes factors such as fuel type, distance traveled and mode of transport (e.g., truck, rail or ship).

The steel supply chain can span hundreds or thousands of miles, making transportation emissions a key variable. For designers and purchasers, this stage emphasizes the importance of sourcing domestic materials from efficient supply chains to reduce emissions.

A3: Steel Manufacturing

A3 is the final step in the product stage, and it captures the impacts of converting the transported raw materials into steel products. Factors to measure in this stage include energy use, waste generation and other environmental impacts within the production facility.

EAF steelmaking uses electricity to melt steel, producing significantly lower emissions at this stage compared to traditional methods, which produce steel through fossil fuel combustion.

By focusing on A1-A3, stakeholders can clearly understand and measure a product’s environmental impact during its most controlled stages. This enables informed decisions to align with a project’s sustainability goals.

How Does A1-A3 Relate to GHG Scopes 1, 2 & 3?

Understanding how the A1-A3 product stage aligns with greenhouse gas (GHG) protocol Scopes 1, 2 and 3 is helpful for evaluating the environmental performance of steel manufacturing. While A1-A3 provides a detailed breakdown of the environmental impacts associated with the production process, GHG scopes categorize emissions based on their source, whether directly from the manufacturer or indirectly from the broader supply chain.

For industry professionals, this connection matters because it bridges material-specific assessments (A1-A3) with corporate sustainability reporting (Scopes 1, 2 and 3), offering a more comprehensive understanding of a product’s carbon footprint. Recognizing how these frameworks intersect empowers decision-makers to meet regulatory standards and showcase transparency in environmental reporting.

Explanation of the scopes:

- Scope 1: Direct emissions from company-owned operations

- Scope 2: Indirect emissions from purchased electricity

- Scope 3: Indirect emissions (upstream and downstream activities)

Interested in learning more? Read about Scopes 1, 2 and 3 emissions in the steel industry.

Mapping A1-A3 to Scopes 1, 2 and 3

A1 Emissions: Raw Material Supply/Extraction and Processing

A1 mainly falls under Scope 3, which involves all upstream emissions associated with initial production, which are GHG emissions that occur before a company receives a product. This could include waste generated from the processing and extraction of raw materials and other upstream emissions generated from the production of material inputs needed for steelmaking. Other upstream examples within EAF steelmaking include purchased steel slabs/ingots/billets and the transportation of inbound raw materials, manufactured products and scrap metal processing. For BF-BOF steelmaking, the A1 emissions are higher than EAF steelmaking due to raw material inputs, carbon intensity and increased energy use.

A2 Emissions: Transportation to Manufacturing/Fabrication

This can include Scope 1 if using company-owned vehicles, but most of A2 is considered Scope 3 because it involves transporting and distributing materials – whether they are iron ore, scrap metal or something else – to the steelmaking facility.

A3 Emissions: Manufacturing/Steelmaking

Direct emissions from the steelmaking facility and fuel usage for on-site transportation of materials (can include diesel, gasoline, propane and natural gas) fall under Scope 1. All purchased electricity falls under Scope 2. If there is any outsourced production or material handling, that would fall under Scope 3.

The A1-A3 stages of the LCA are particularly relevant to Scope 3, which addresses upstream and downstream supply chain impacts. Understanding this relationship allows steel manufacturers to identify where the largest supply chain emissions occur and implement targeted strategies to reduce them, such as optimizing transportation or increasing the use of recycled materials.

Why Should We Measure A1-A3 and GHG Scopes 1, 2 and 3?

Measuring LCA A1-A3 (cradle-to-gate) impacts, as well as GHG Scope 1, 2 and 3 emissions, offers significant benefits for steel purchasers, engineers and manufacturers:

- It provides transparency around sustainability impacts for individual materials and overall operations.

- It enables companies to work towards reducing carbon emissions by identifying emissions hotspots in A1-A3 or Scope 1, 2 and 3 processes.

- It helps professionals select materials and energy sources that align with their sustainability goals and regulatory requirements.

Challenges can arise due to the complexity of collecting reliable data or misalignment between LCA stages and scope categories, which can create inconsistencies or leave areas unaddressed. Therefore, it’s important to purchase from manufacturers who provide clear reporting.

Nucor is proud to be an industry leader in GHG data transparency through third-party verified reporting. Our emissions data is publicly available in our corporate sustainability report and our growing portfolio of environmental product declarations (EPDs), which include A1-A3 reporting.

If you’re interested in planning your next project with sustainability in mind or have questions, reach out to the Nucor Construction Solutions team.