How to Make Steel: Blast Furnace Vs. Electric Arc Furnace

The green economy is being built on steel. Steel is foundational to the longevity and durability of the built environment because of its strength – but many designers and specifiers don’t fully understand why the steel they build with matters.

Steel is an essential engineering material that is versatile, durable and infinitely recyclable. From high-rise buildings and data centers to wind turbines and electric vehicles, steel will be a critical component for building a sustainable future. Yet today, the steel industry contributes approximately 7-9% of global CO2 emissions according to Worldsteel.

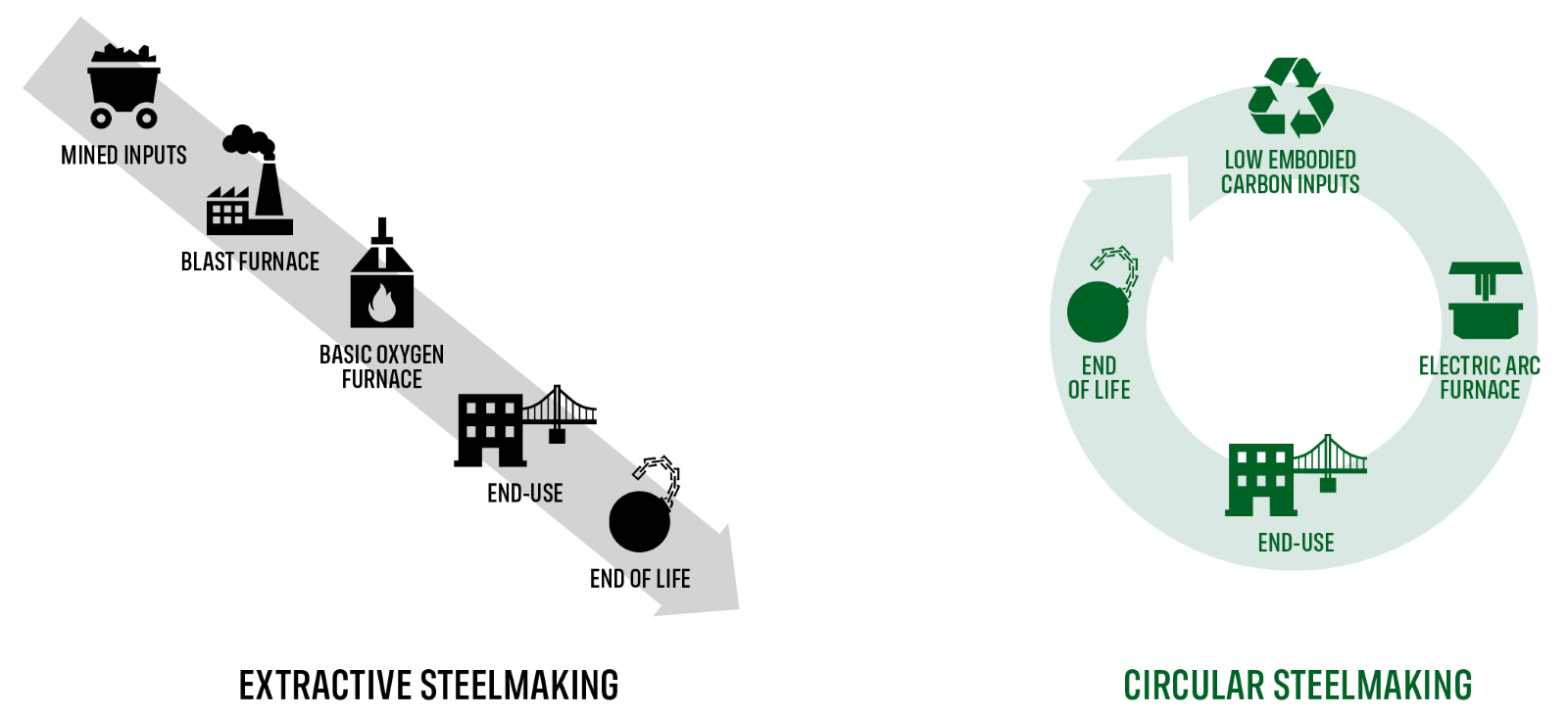

A truly green economy will be one built with green, low-embodied-carbon steel. That’s why it is essential to understand that there are two primary ways to make steel – blast furnace and electric arc furnace – which yield significantly different greenhouse gas (GHG) intensities embodied in the steel they produce.

BLAST FURNACE STEELMAKING

Integrated or Extractive Steelmaking: Blast Furnace (BF) and Basic Oxygen Furnace (BOF)

A typical blast furnace used by a traditional, extractive steel mill.

A typical blast furnace used by a traditional, extractive steel mill. The integrated steelmaking process, also known as extractive steelmaking, is the traditional method for producing steel. It starts with mining raw materials out of the ground, including iron ore, limestone and coal. These materials are melted in an energy-intensive blast furnace (BF), which reacts iron oxide and carbon (in the form of coke, a porous coal-based fuel) to form two products: iron (saturated with carbon) and CO2. Liquid iron from the blast furnace is then reacted with oxygen in a second step via a basic oxygen furnace (BOF) to remove excess carbon, producing even more CO2. This reduced form of iron is steel.

The extractive process is particularly emissions-heavy because CO2 is a byproduct of both steps along the way – the blast furnace and the basic oxygen furnace. Furthermore, the process always requires the extraction of natural resources from the earth. While the extractive method of steelmaking has been used for hundreds of years and remains widespread, a modern and significantly more sustainable process is available – circular electric arc furnace steelmaking.

ELECTRIC ARC FURNACE STEELMAKING

Circular Steelmaking: Electric Arc Furnace (EAF)

One of Nucor’s circular EAF steel mills.

One of Nucor’s circular EAF steel mills. Circular steelmaking, powered by the electric arc furnace (EAF) in what are often called mini mills, is a recycling-based steelmaking process that uses electricity to melt scrap and other inputs into new, high-quality steel.

The circular steelmaking process is significantly less emissions-intensive and more sustainable than the integrated steelmaking process.

By recycling scrap as a primary source of iron, the circular process keeps more carbon intensive materials in the ground – conserving natural resources – and helps to mitigate the emissions associated with mining and both blast and basic oxygen furnaces. Using electricity as a primary source of energy instead of coal combustion is much cleaner, and if electricity from renewable or carbon-free electricity sources is combined with high percentages of scrap usage, the carbon footprint of this process drops substantially.

Nucor’s circular steelmaking process starts with recycling steel from end-of-life scrap collected from things like decommissioned buildings, old cars and appliances, excess scrap metal collected from our customer and partner fabricators and stampers creating the circular steel process. This scrap is melted using electricity in an EAF to create new high-quality steel. The use of scrap eliminates the need for the series of chemical reactions in a BF-BOF that produce high amounts of CO2. The process becomes circular when steel products come to the end of their useful life: Nucor buys the scrap to recycle again into new steel.

This cycle can continue infinitely without any loss in steel quality, promoting a more sustainable future to move the green economy forward.

HEAD-TO-HEAD: Blast Furnace Vs. Electric Arc Furnace

Comparing Greenhouse Gas Emissions Intensity for Steelmaking

The difference in inputs and processes between the BF-BOF (extractive) and EAF (circular) steelmaking methods results in a significant difference in total CO2 emissions.

- The extractive BF-BOF process, on average, emits 2.33* tons of CO2 for every ton of steel produced for Scopes 1-3 of carbon emissions reporting.

- In comparison, Nucor’s circular EAF process emits only 0.77* tons of CO2 per ton of steel produced for Scopes 1-3. That’s less than one third the GHG intensity of BF-BOF steelmaking.

This means that the source of steel for a project can impact a project’s carbon footprint in a significant way.

For example, the automotive industry is expected to put 350 million electric vehicles (EVs) on the road by 2030, with each EV requiring about 1 ton of steel. If these EVs are built with extractive steel, about 816 million tons of CO2 will be emitted to produce the required steel. However, if circular steel is used, only about 270 million tons of CO2 will be emitted to produce the necessary steel. That’s a staggering differential of 546 million tons of CO2 emissions – approximately 67% mitigated by using circular EAF steel.

NUCOR IS A LEADER IN SUSTAINABLE STEELMAKING AND INDUSTRIAL DECARBONIZATION

Today, Nucor is North America’s largest steel producer and recycler. For more than 50 years, we’ve pioneered circular steelmaking, starting with our first EAF mill in 1969. Since our inception, Nucor has never used traditional blast-furnace technology – all of our mills use EAFs to make steel the sustainable way.

But we’re not stopping there.

- Nucor is committed to net-zero, science-based greenhouse gas targets for 2050, which includes Scopes 1, 2 and 3. Our targets are based on the Global Steel Climate Council’s Steel Climate Standard, which has broader boundary definitions than Worldsteel.

- We are continuing to drive our industry forward through investments in near-zero GHG iron making technologies like carbon sequestration at our direct reduced iron (DRI) plant in Louisiana, and alternative near-zero ironmaking technologies like Electra and Hisarna.

- We continue to reduce consumption of electricity generated with fossil fuels by exploring nuclear energy alternatives that could provide carbon-free electricity to its mills, investing in power purchase agreements (PPA), promoting renewables, and entering into partnerships with other large electricity users like Google, Microsoft and Amazon in order to scale the adoption of advanced clean electricity technologies.

Projects like these will allow Nucor to continue increasing the sustainability of its operations and advance the decarbonization of our industry.

The green economy is in motion, and it will require a reliable supply of high-quality, sustainably made steel to ensure its success.

Curious about how Nucor is committed to helping you reach net-zero by 2050? Learn more about sustainability at Nucor.

Learn More