Together with our partners, we’re leading the charge to create a more sustainable future.

Let's ChatMade for Good

ENERGY CASE STUDY

WHAT IF THE FUTURE OF STEEL IS THE FUTURE OF CLEAN ENERGY?

Nucor has established multi-disciplinary teams to investigate technologies and operational adjustments we can deploy to further reduce the GHG intensity of our production processes.

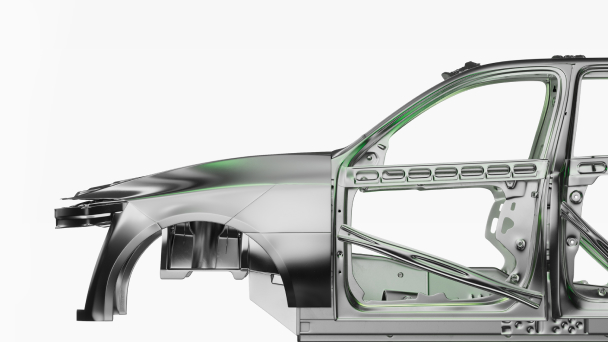

Sustainability has long been the foundation of Nucor, the largest producer and recycler of steel in America. Since Nucor entered the steel business more than 50 years ago, it’s been a leader in the adoption of pioneering innovations such as electric arc furnace (EAF) technology, a circular process that upcycles scrap metal into new steel products.

Consequently, Nucor stands out as one of the most environmentally friendly steel producers globally, with an emissions intensity that is that is less than one-third the global average of extractive steelmaking methods using blast furnaces for Scope 1, 2 and 3 emissions. Additionally, Nucor is 20 years ahead of the Paris Agreement's 1.5°C scenario, demonstrating its exceptional commitment to combating climate change.

Nucor remains steadfast in the pursuit of excellence for ourselves and our partners, committing to net-zero, science-based greenhouse gas (GHG) targets for 2050, which include Scopes 1, 2 and 3. As a large energy consumer, this includes investing in clean energy sources and power generation technologies to decarbonize our operations and accelerate the transition to a more sustainable future.

While renewables such as wind and solar have been crucial supplements to fill the energy gap as more fossil fuel plants in the U.S enter retirement, renewables alone lack the scale and reliability required for energy-intensive industrial applications such as steelmaking. As a result, they must be paired with a reliable baseload power source.1

Nuclear is currently one of the strongest contenders for meeting energy needs on this massive scale with clean and carbon-free power. Nucor has partnered with NuScale, a leader in new nuclear technology, to explore developing more powerful, reliable, and affordable nuclear power options.

NuScale is developing Small Modular Reactors (SMR), an advanced nuclear technology that can produce carbon-free electric power on a smaller scale and at a lower cost than traditional nuclear. NuScale’s groundbreaking VOYGR™ plants can generate the same amount of power in just 0.05 square miles that wind turbines would require 94 square miles for, creating new opportunities for consistent on-site power. Each plant can be scaled to provide up to 924 MWe of output or enough electricity to power 700,000 homes.2

As the first design of its kind to receive Nuclear Regulatory Commission approval, the VOYGR™ plants have the potential to transform power generation and consumption at an industrial scale.

In April 2022, Nucor announced a $15 million strategic investment in NuScale to support the commercialization of NuScale’s innovative technology. In addition, the two companies will explore colocating NuScale's VOYGR™ plants to provide clean, reliable baseload electricity to Nucor's scrap-based EAF steel mills. This benefit could be extended to surrounding businesses and communities to build energy independence via a flexible, affordable electricity source.

The companies will also explore an expanded manufacturing partnership through which Nucor, the largest steel producer and recycler of any type of material in North America, would supply Econiq™, its net-zero steel products, for NuScale projects. Econiq is made using 100% renewable electricity (eliminating Scope 2 emissions), with Scope 1 emissions offset and can be applied to any steel product within the Nucor family.

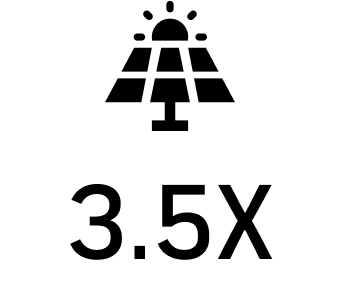

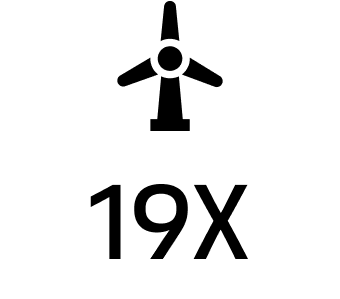

To generate the same amount of electricity as one 12-module SMR, you would need almost 3.5x the land area with a solar farm or almost 19x the land area with a wind farm.

Enough clean electricity to power a steel mill

- $15 million strategic investment in NuScale to support the path to commercialization of its technology

- Exploring expanded manufacturing partnership through which Nucor would supply Econiq™ steel, for NuScale projects

- Studying the feasibility of siting a manufacturing facility for NuScale Power Modules™ near a Nucor facility

NuScale is thrilled to take this step forward with Nucor, a company that shares our commitment to sustainability and deeply understands the role of NuScale’s technology to support the global energy transition.

NuScale President and CEO

Nucor is committed to funding and scaling emerging clean energy technologies. This partnership with NuScale not only helps pave the way for a carbon-free energy future for the steelmaking industry but works with entrepreneurs in the space to build it using some of the cleanest steel products in the world.